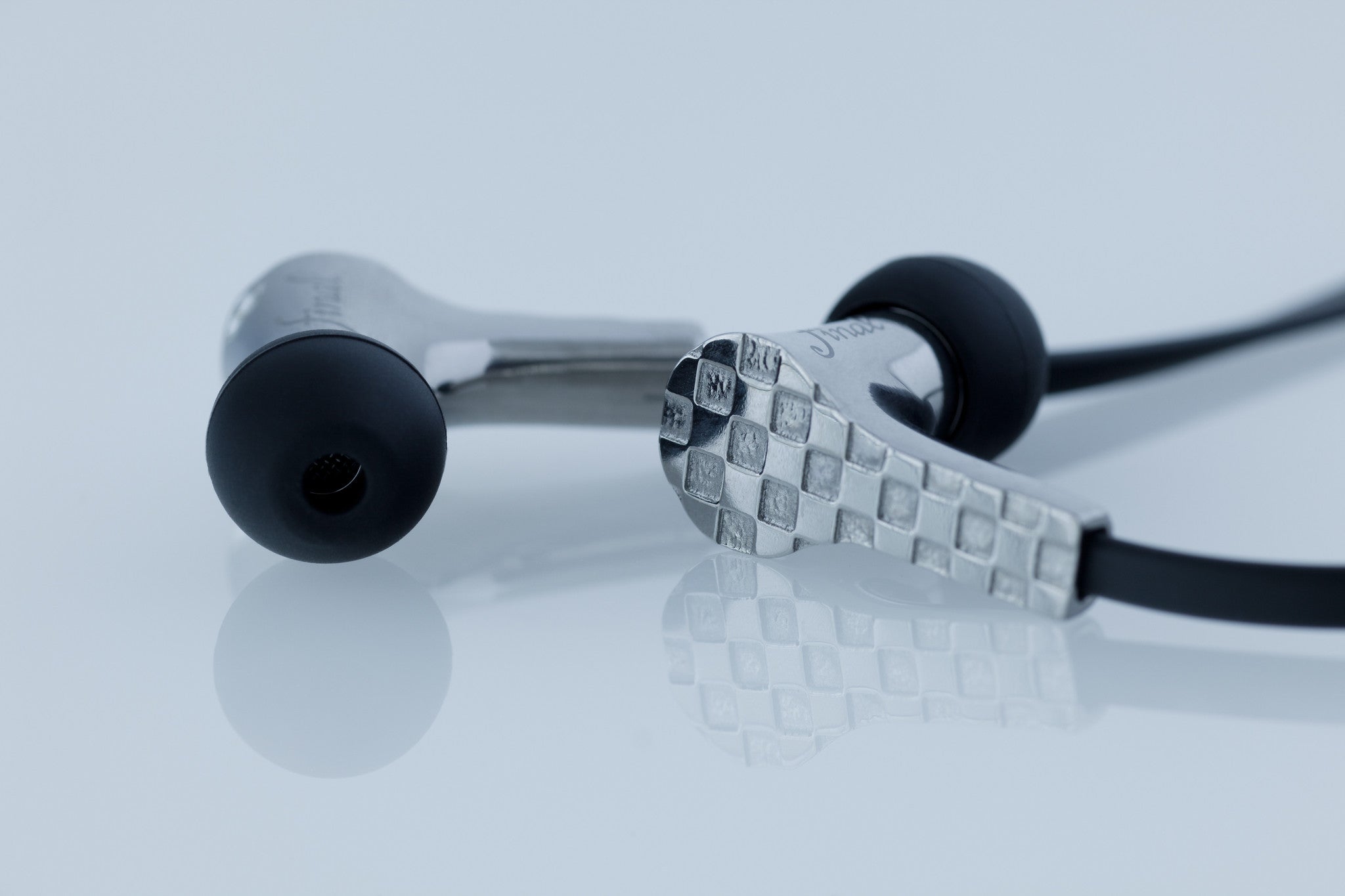

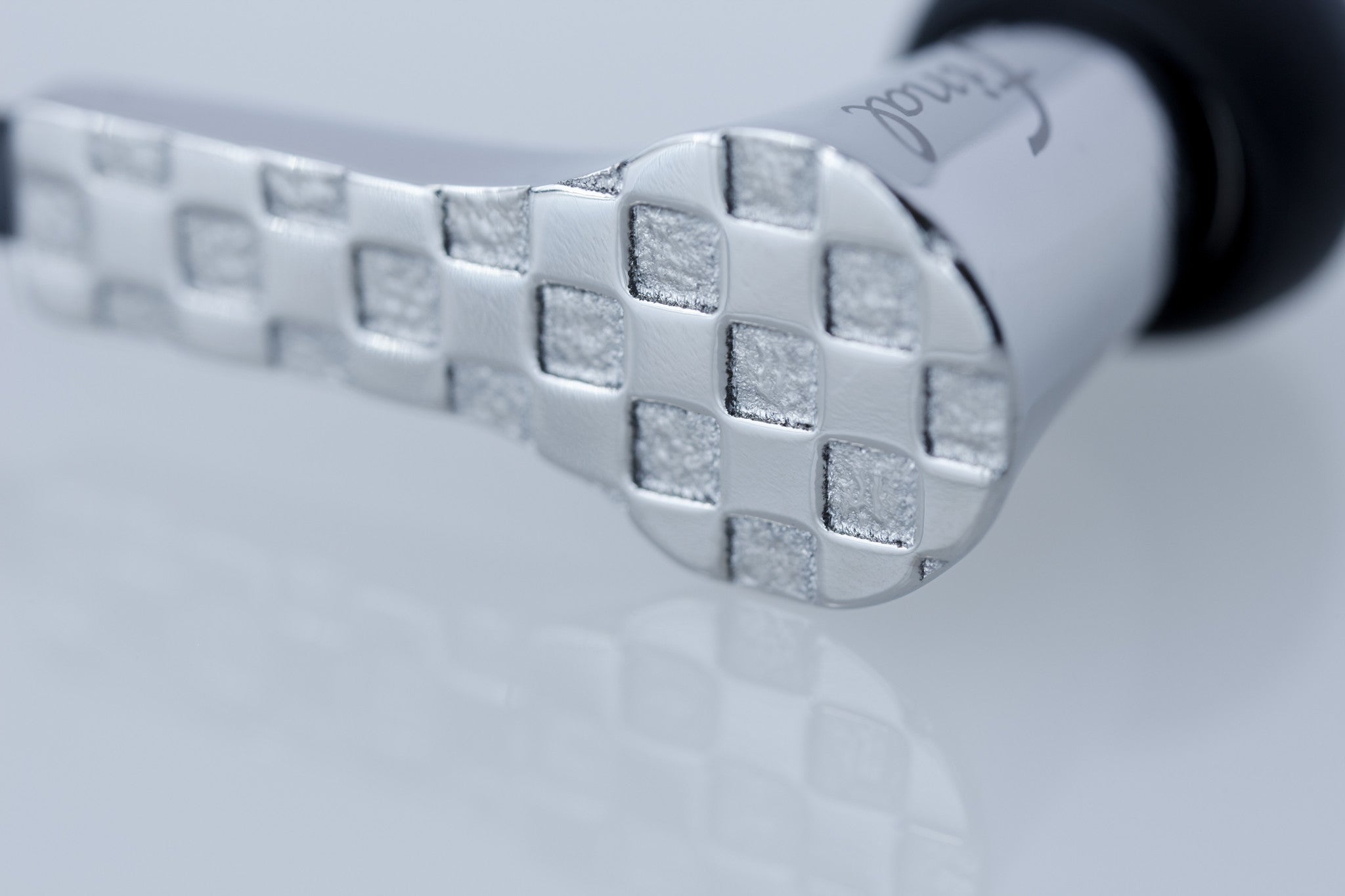

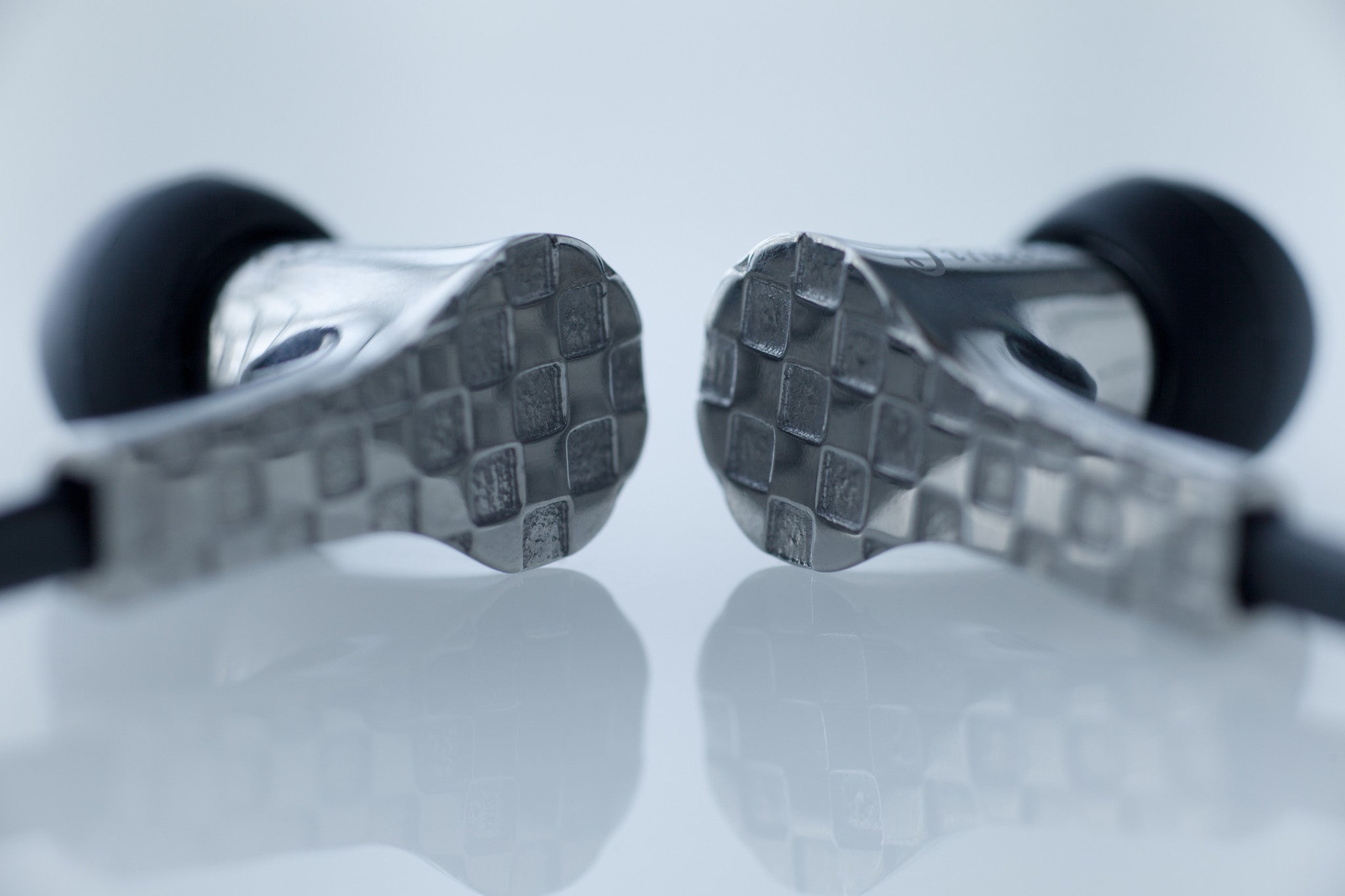

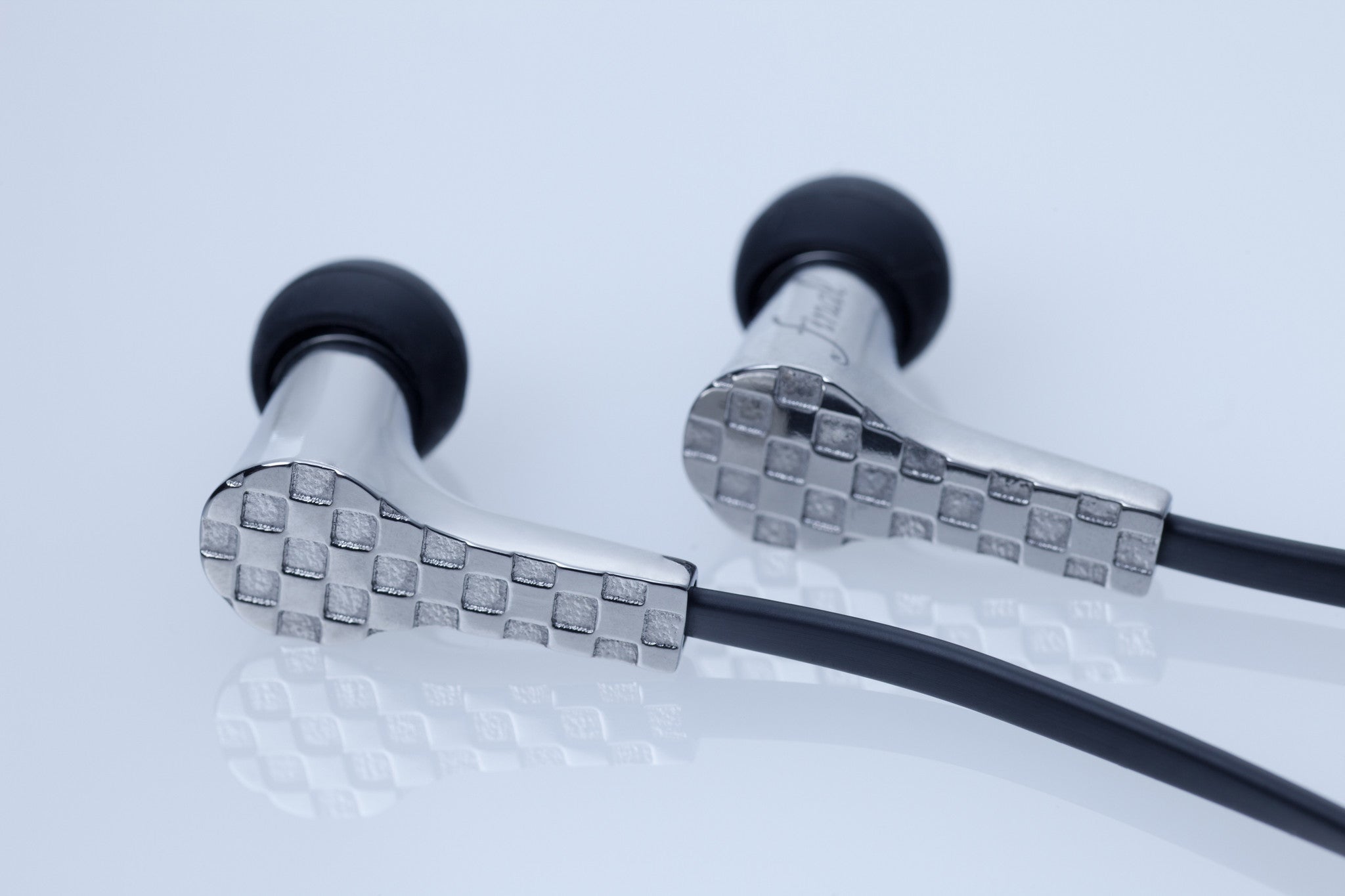

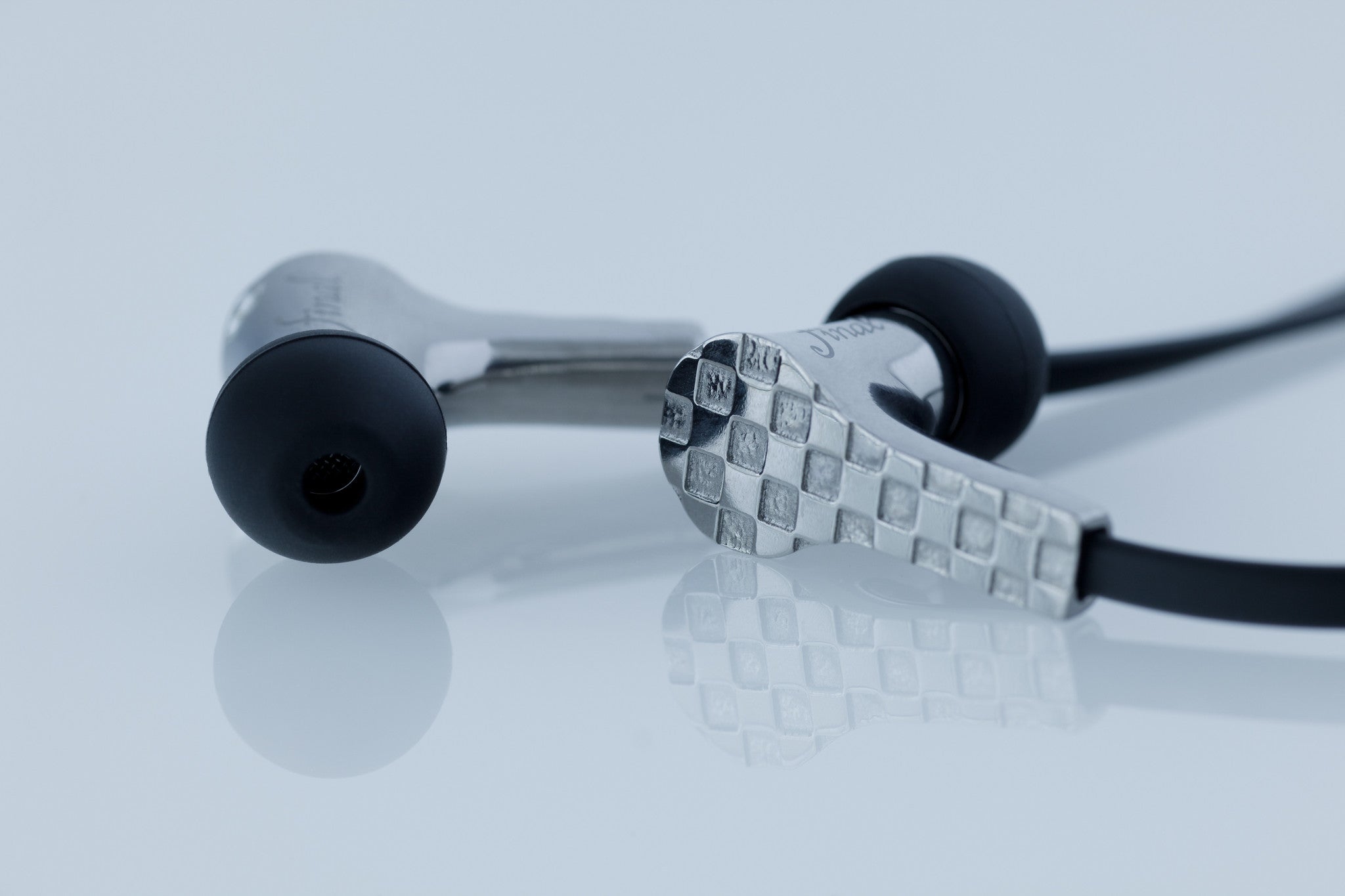

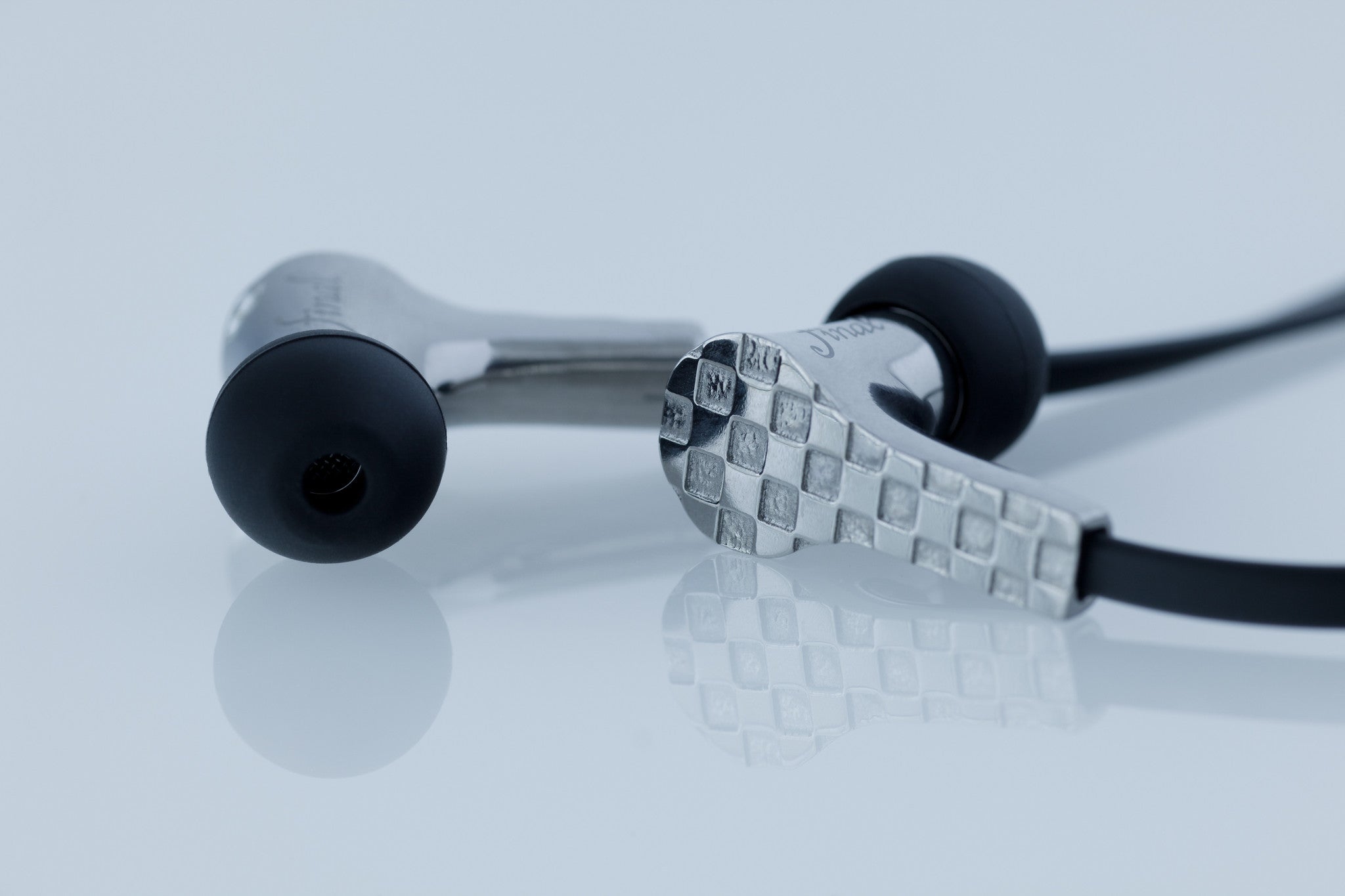

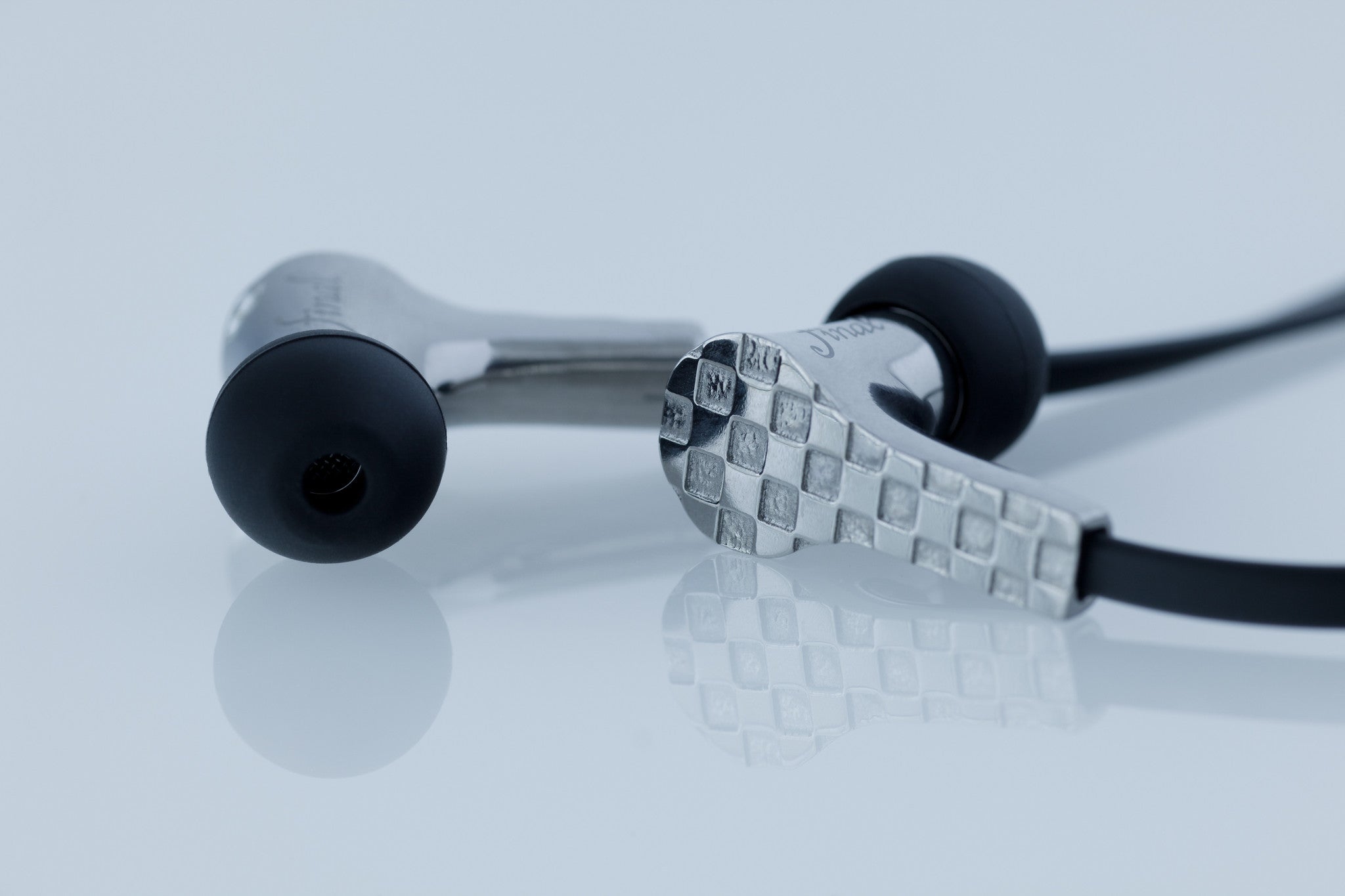

Final LAB I

Tax excluded. Shipping calculated at checkout

Pickup available at Jaben @ The Adelphi

Usually ready in 24 hours

Final LAB I

Jaben @ The Adelphi

1 Coleman St, #01-25

The Adelphi

Singapore 179803

Singapore

Final LAB I

Sale price$2,418.69 SGD

Regular price$2,418.69 SGD (/)

Final LAB I

Sale price$2,418.69 SGD